When you get a new boat, all the lines are beautifully coiled and wrapped. They’re soft and flexible, and virtually silent when stressed. Over time, because of wear, salt water and UV degradation, they get stiff, they begin to fray, and they make terrible squealing and cracking noises. I hate that.

We just replaced our main halyard back in February with a beautiful Vectron blend line. It’s already starting to stiffen and make noise when we hoist the sail. But, to its credit, it did just spend three months working out in the hot sun and the salt air in the Exumas.

The jib sheets will most likely need to be replaced later this year, not because of stiffening, but because they are showing signs of fraying. The sheathes are getting fuzzy. We would probably get another two years out of them, but why risk it? When the wind is blowing 25 knots, you don’t want lines to separate. That would suck.

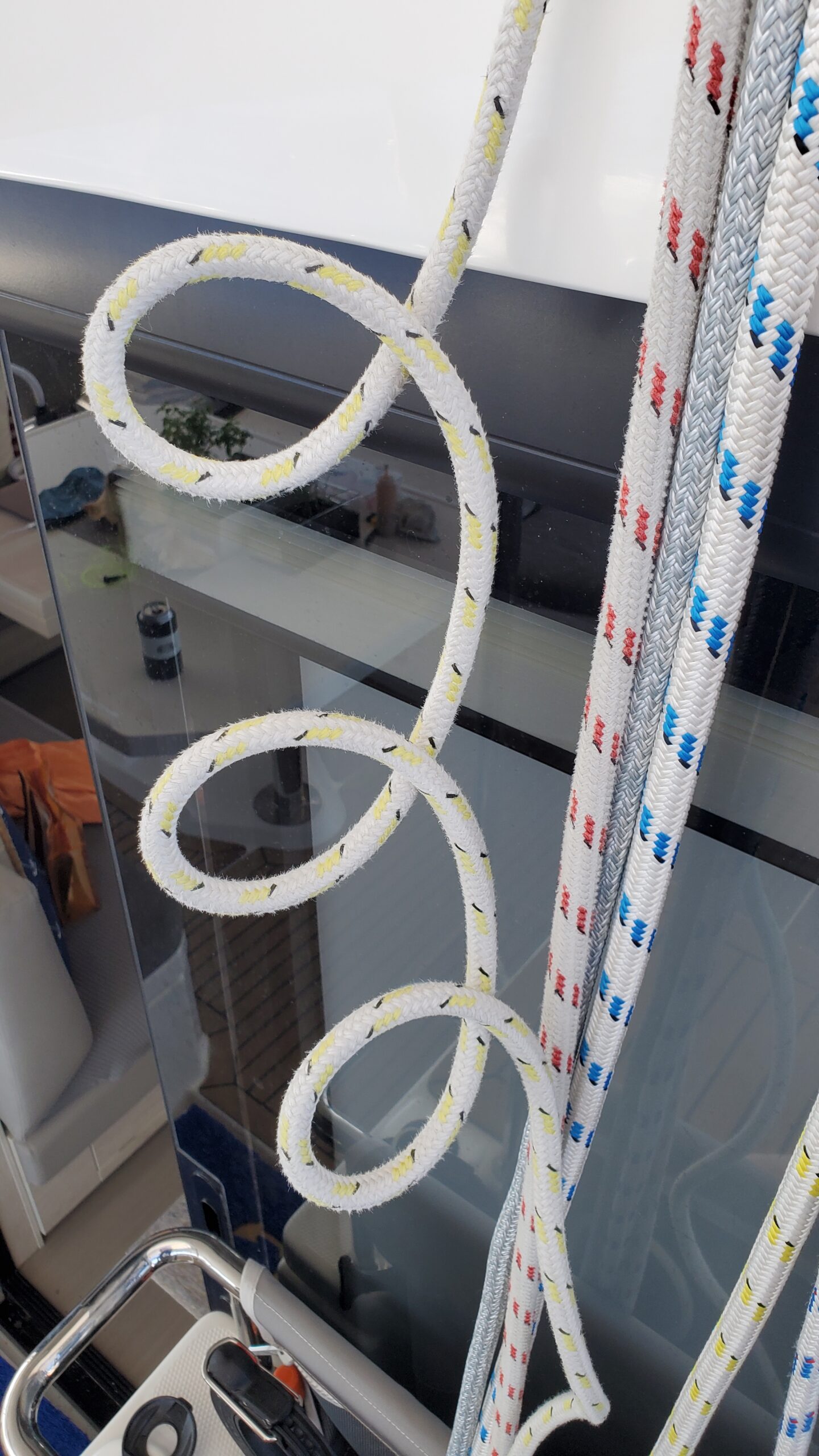

And then there’s this line. This is our jib furling line. For those of you who don’t know what that is, this is the line we use let out (unfurl) and put away (furl) our jib (head sail). It’s definitely showing signs of wear. Don’t you think? This picture was taken after we furled the sail. To do this, we wrap this line around the electric winch and crank away. This rolls the jib around the forestay. And I’m pretty sure that once that task is complete, this line should straighten out and be easily lowered into the line bag.

I guess it’s time to replace this one, too. It’s always something.

April 2021